On to Machine Shop Special Projects - Sub-scale Muzzleloading Artillery

Now we are going to drill the bore. Real bore drilling uses gun drills, which are specialized drills that cut more

like an end-cutting boring bar and require high pressure oil to force the chips out of the hole. We aren't that sophisticated.

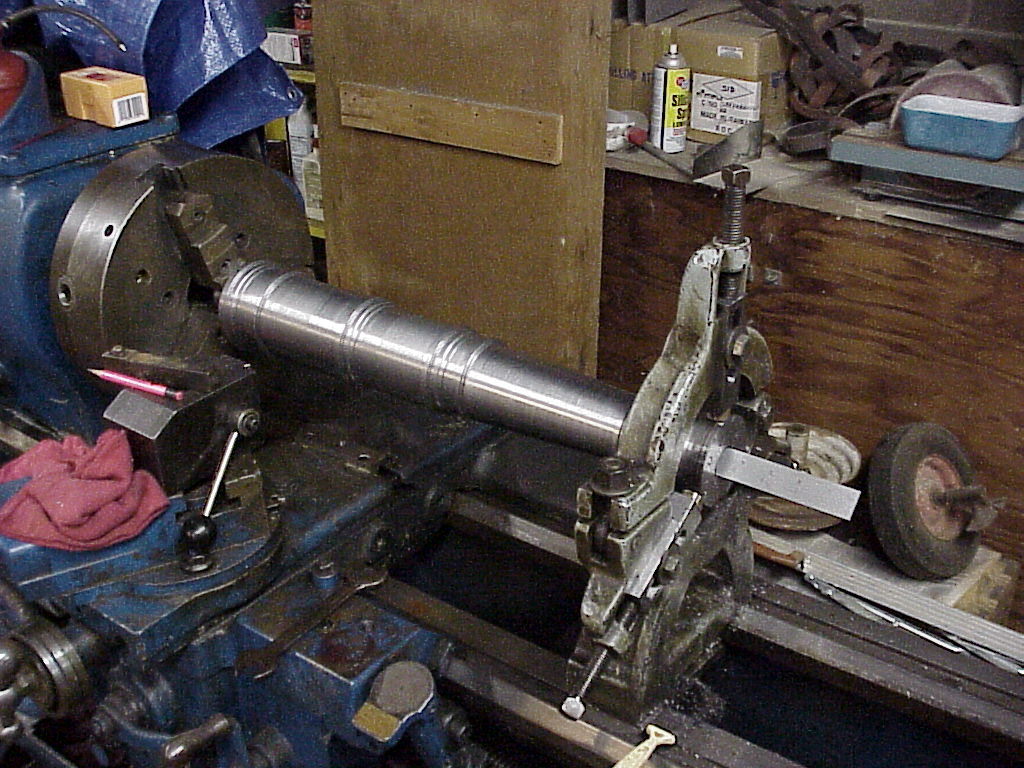

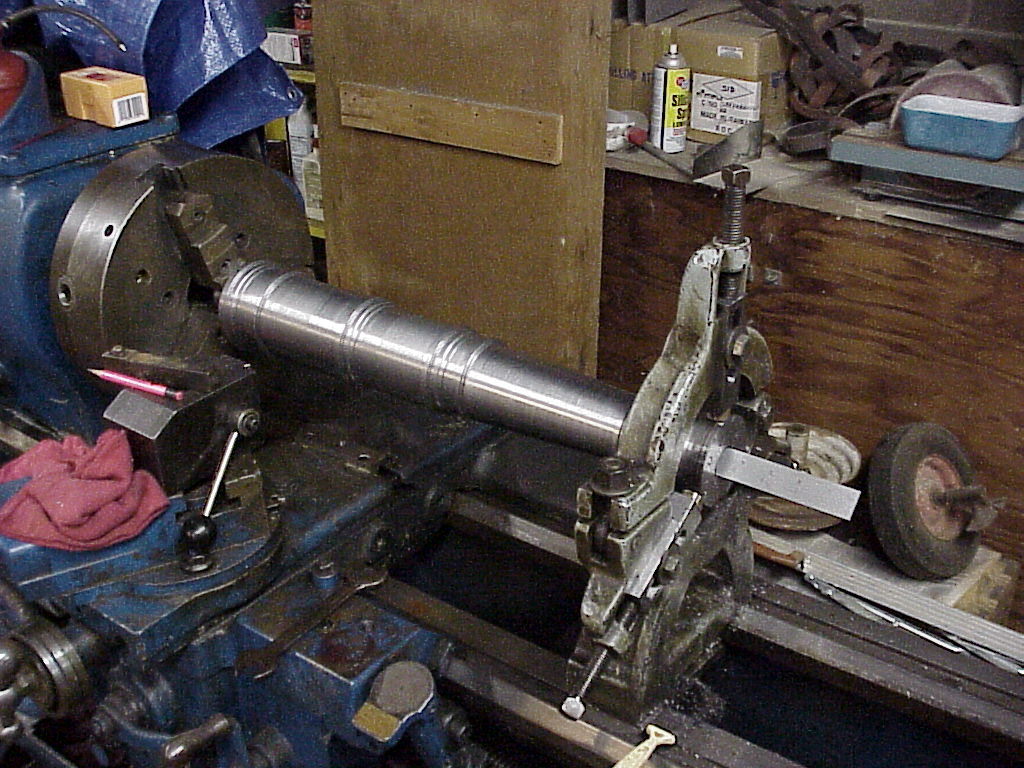

First, we move the barrel to my 17x54 lathe so we have room for the drills. We'll start the hole with a

regular 1" Morse taper twist drill and drill the deepest hole we can with it. When that is finished,

the barrel looks like this.

The 12 inch rule is sticking out about 5 inches. Next we will continue drilling with the school's 24" long by 1" diameter drill,

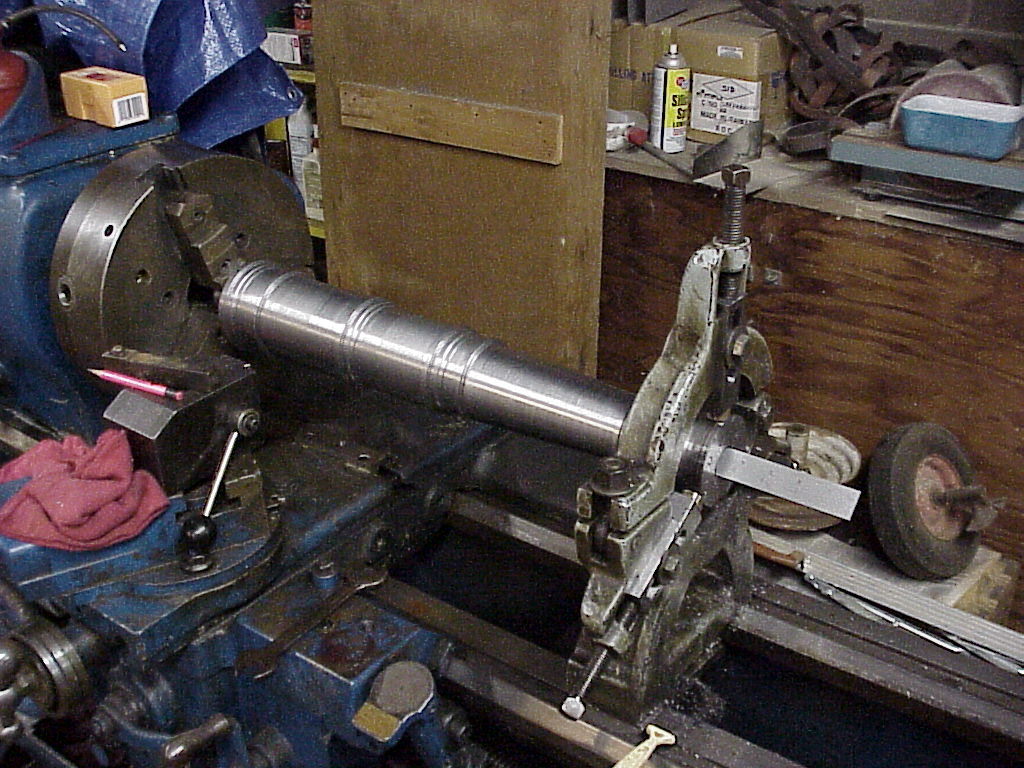

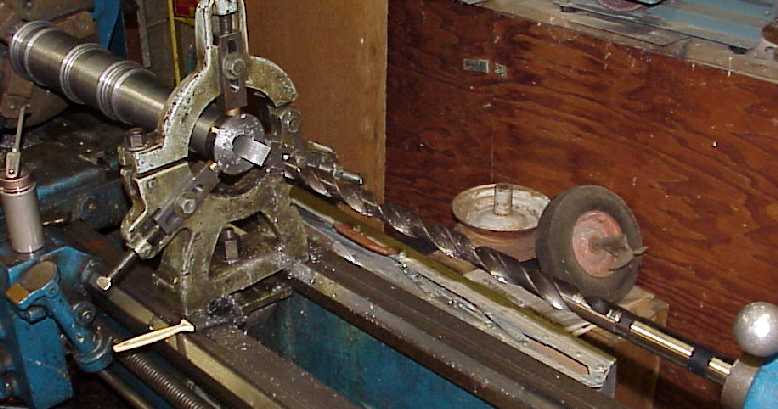

bought specifically for drilling cannon barrels. After a long period of drilling a quarter inch or so at a time, we have

reached 10" in depth. The hole looks like this and so does the drill.

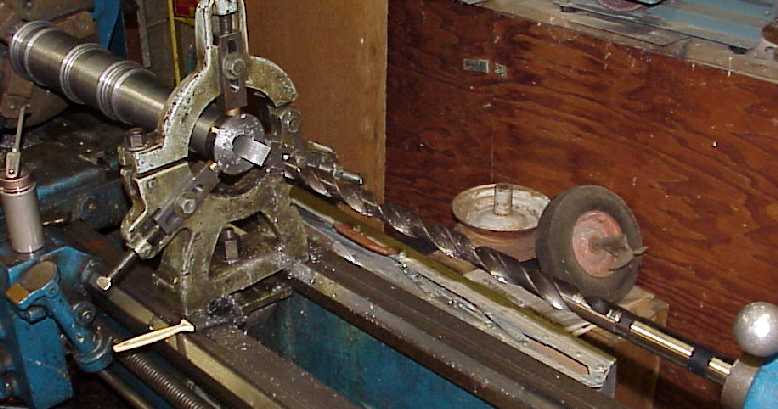

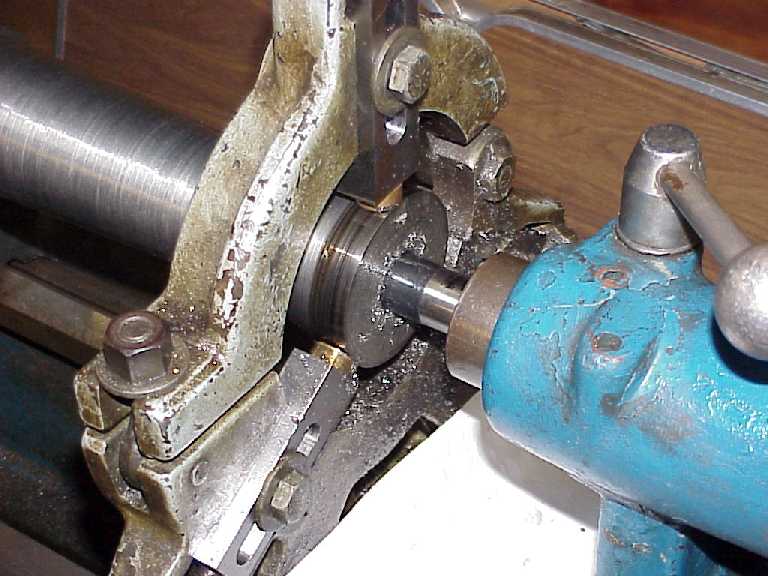

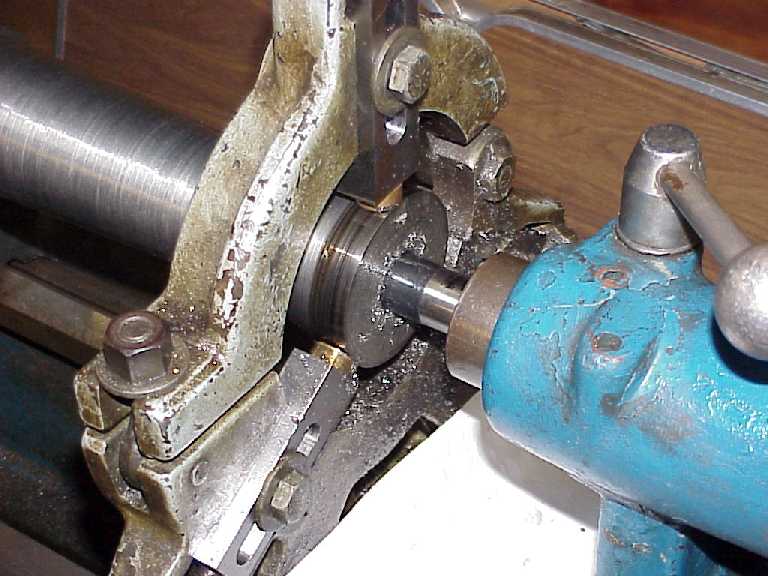

The ultimate hole depth is the black tape around the drill body (closest to the tail stock.) Here is the bore drilled to a 12" depth.

Followed by the drill in all the way.

This pile of chips is what came out to make the bore. It's about 4" deep at the deepest.

Next we will finish the muzzle and the mouldings.