On to Machine Shop Special Projects - Sub-scale Muzzleloading Artillery

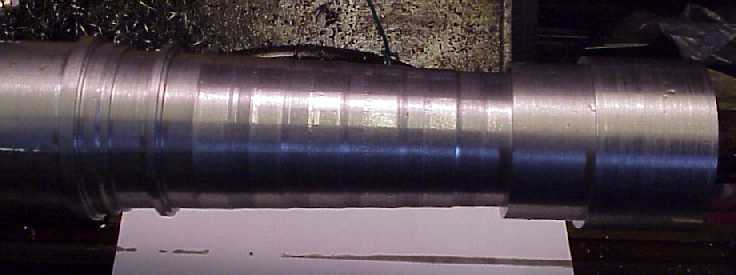

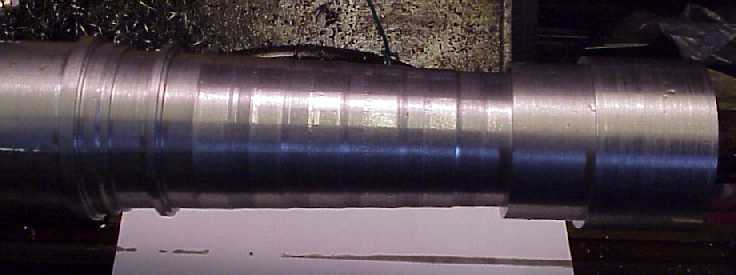

Before we can do any detail work on the chase and muzzle of the gun, we need to remove over an inch of diameter for most of the remaining length. The barrel now looks as follows:

The blob on the right has already been reduced from 4 3/8" diameter to 4" diameter; it needs to go to 3 1/4" for the last 2" and under 3" for the remainder. Here it is in that state:

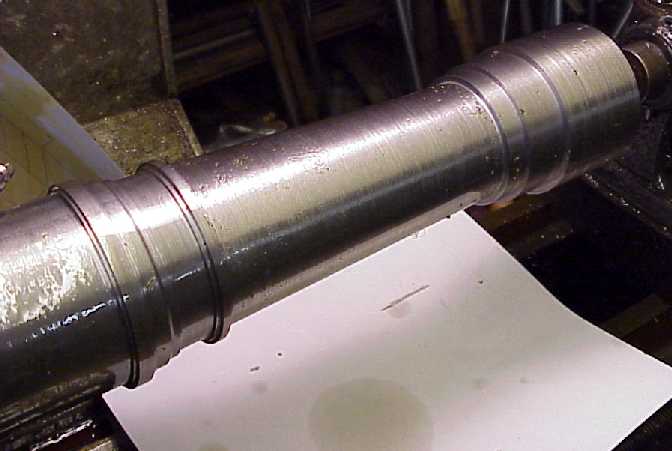

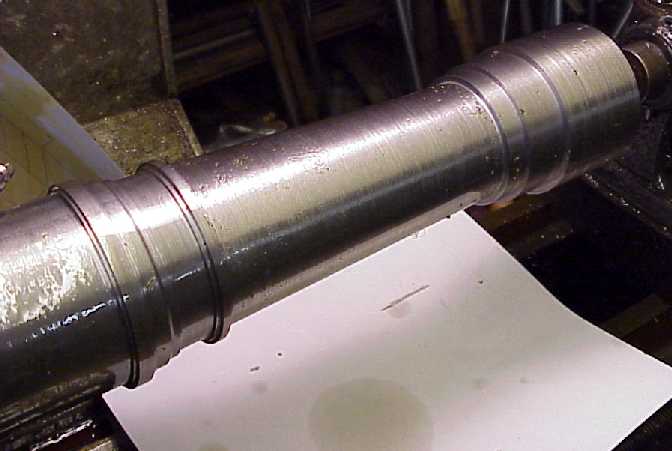

Next we will locate the front fillet/astragal/fillet combination and then do the taper. Since I am machining this barrel on one of my home shop lathes, we will have to do the taper by turning a series of steps (instead of offsetting the tailstock) because this machine cannot offset the required amount. So first we will remove six steps .040" deep and 1" long.

Then, so the finish taper has a limited change to the depth of cut, we will go back and add .020" deep cuts to the larger half of each step. To finish the taper, we will make a series of .001" x .0245" steps so we won't have to file for smoothness too much.

Next we will do the fillets and astragal behind the muzzle and the curve on the back side of the muzzle.